Long Life Fasteners:

ZAC®, Impax™ ZAC®, Impax™ MAC™, woodZAC®, woodMAC™ and everGrip® Fasteners

SFS intee, Inc., hereby provides this limited warranty to the buyer of the fasteners from SFS inlee. SFS intec warrants the head of its defined long life fasteners against red rust corrosion and structural failure, as defined below, due exclusively to red rust corrosion failure of the head of the fastener resulting from I, exposure to normal atmospheric corrosion for the life of the building, subject to the express conditions stated below.

Notification of a claim under this warranty must be submitted in writing within thirty days after discovery of a warranted failure, to SFS intee, Inc., P.O. Box 6326, Wyomissing, PA 19610. SFS will examine, or cause to be examined, the fasteners in question. Buyer will furnish adequate identification on the I fasteners involved in the claim and date of shipment.

SFS shall make the exclusive determination as to whether a failure within the terms of this warranty has occurred. If it is determined by SFS intec that a breach of warranty has occurred, SFS will provide replacement fasteners in quantities sufficient to permit buyer to fully replace all failed fasteners or refund I to buyer the original cost of the failed fasteners. SFS intec' sale responsibility for breach of this warranty shall be limited exclusively to replacement of the failed fasteners, or at the sale optlon of SFS intec, to refund the original cost of the failed fasteners.

Structural failure of the fastener due to red rust corrosion will be deemed to have occurred when the fastener will no longer reta in the panel as required in a normal application due exclusively to the failure of the head of the fastener as a direct resu lt of red rust corrosion. Red rust corrosion failure of the fastener will be deemed to have occurred when the fastener has red rust corrosion on the head of the fastener.

This warranty DOES NOT APPLY to any fasteners exposed to corrosive or aggressive atmospheric conditions including, but not limited to, areas subject to tide or salt water, fallout or exposure to corrosive chemicals, ash, fumes, nuclear radiation, acid rain, or where corrosive fumes or condensates are generated or released inside the building.

This warranty DOES NOT APPLY if the failure was caused by improper application of the fastener, use of faulty or worn sockets, in-transit or job site damage, improper installation of the fastener, external forces, explosions, fires, "acts of God", or natural disasters. This warranty applies only to buyer and is not transferable or assignable.

THE WARRANTY AND REMEDIES STATED HEREIN ARE EXCLUSIVE OF AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PURPOSE. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, EXCEPT THOSE STATED HEREIN. UNDER NO CIRCUMSTANCES SHALL SFS INTEC'S LIABILITY UNDER THIS WARRANTY EXCEED THE AMOUNTS STIPULATED ABOVE, NOR SHALL SUCH LIABILITY BE CONSTRUED AS EXTENDING TO ANYTHING OTHER THAN THE COST OF REPLACING FAULTY FASTENERS. IN NO EVENT SHALL SFS INTEC, INC. BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF THE FASTENERS, OR ANY BREACH OF THIS WARRANTY

v. July 2015

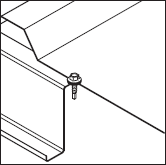

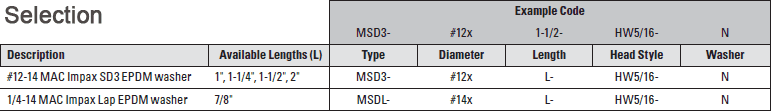

Drilling capacity: .035 – .210" Thickness is based on normal, single thickness purlin/girt or multiple material thickness combined for total, as in overlapped or nested purlin construction. Min projection: 3/16" of threads below substrate

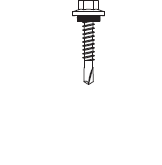

5/16" AF Stainless Capped

Hex Washer Head

Thread Major Dia: .215 – .209

Thread Minor Dia: .164 – .157

Strength (lbs ult.):

Tensile: 2900

Torsional: 92 in-lbs

Shear: 2050

Pull-out (lbs ult.):

12 ga (.105): 1524

14 ga (.075): 901

16 ga (.060): 665

Pull-over (lbs ult.):

22 ga (.030): 1298

24 ga (.024): 1102

26 ga (.018): 692

Drilling capacity: .030 – .095"

Some applications may require attaching light gage (24 – 26 ga) to sub-structural member.

Composite thickness should not exceed .095" thickness.

5/16" AF Stainless Capped Hex

Washer Head

Thread Major Dia: .246 – .240

Thread Minor Dia: .192 – .185

Strength (lbs ult.):

Tensile: 3800

Torsional: 150 in-lbs

Shear: 2850

Pull-out (lbs ult.):

22 ga (.030): 379

24 ga (.024): 304

26 ga (.018): 204

Dimensions are nominal inches unless noted. Self-drill pull out values (pounds ultimate) are based on 57,000 psi hot rolled steel material. Lap self-drill pull out values are based on 40,000 PSI AZ55 Galvalume steel sheet material. Ultimate values listed are the result of laboratory testing (5083.14). The specific job conditions should be considered and appropriate safety factors applied when specifying the proper fasteners. #12 fasteners 1" and longer have special long pilot lengths to accommodate nested purlins.

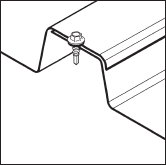

Tools: 0 – 2000 rpm screw gun equipped with depth sensing nose piece.

Use of impact guns or hammer drills is not recommended.